Why You Required Stretch Wrapper Repair Service: Discovering Its Role in Ensuring Product Packaging Quality and Security

Stretch wrappers play a crucial duty in the product packaging procedure by guaranteeing the stability and integrity of bundled items. Nonetheless, they can encounter different concerns that demand timely repair services. Ignoring these repair services can cause considerable inefficiencies and potential item damages. Comprehending the implications of stretch wrapper maintenance is vital for any service. This discussion will certainly check out how normal repair work add to packaging top quality and security, inevitably impacting the entire supply chain.

Recognizing the Significance of Stretch Wrappers in Product Packaging

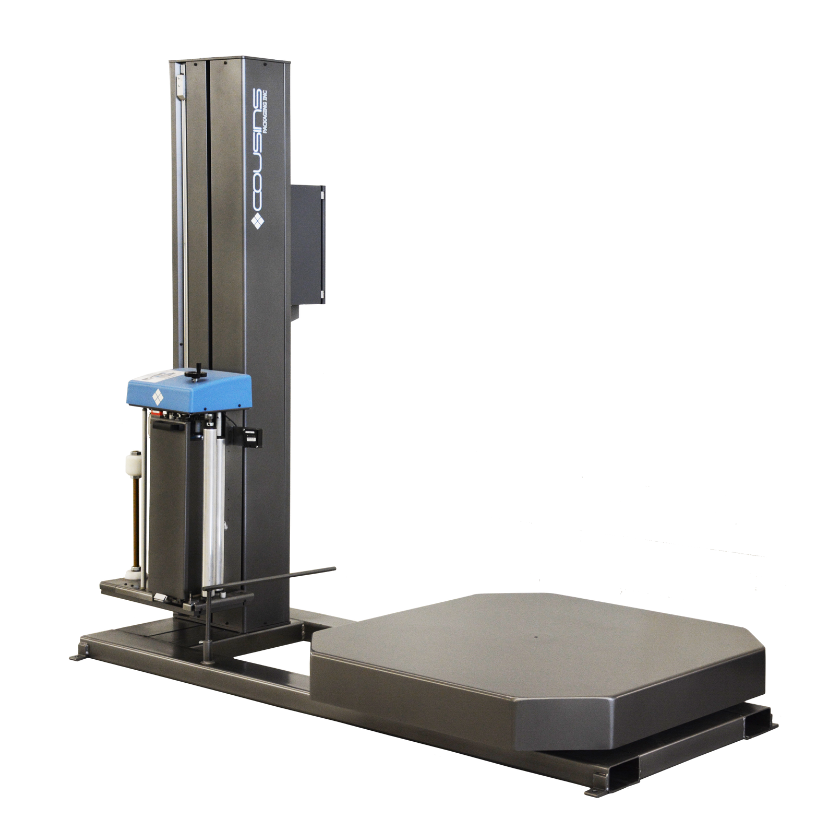

Although typically forgotten, stretch wrappers play a vital role in the packaging procedure for various markets. These equipments ensure the safe and secure bundling of items, improving security and safeguarding things throughout transport. By securely covering products in stretch movie, they reduce the threat of damages from shifting or environmental factors.In sectors like food, pharmaceuticals, and manufacturing, reliable product packaging is crucial for preserving item stability and safety and security (stretch wrapper repair). Stretch wrappers contribute to this by reducing the probability of contamination and spoilage, thereby prolonging shelf life. Additionally, their efficiency advertises cost-effectiveness; companies can enhance packaging operations, minimizing labor costs and time.Moreover, stretch wrappers can fit numerous product forms and dimensions, making them flexible devices in packaging. Their capability to satisfy different loads ensures that even irregularly shaped products are protected effectively. To sum up, the importance of stretch wrappers can not be undervalued in the pursuit for high quality product packaging solutions

Usual Issues That Demand Stretch Wrapper Fixing

Stretch wrappers, while essential for keeping packaging integrity, can encounter numerous functional problems that require repair work. Common troubles consist of inconsistent stress, which might result in loose or damaged loads, jeopardizing product protection during transportation. Additionally, malfunctioning sensors can interrupt the wrapping process, causing unequal application of stretch film. Damaged rollers or belts may create slippage, preventing the wrapper's performance and triggering delays in manufacturing. Issues with the control system can lead to inappropriate settings, influencing the general wrapping top quality. Dust and debris build-up in mechanical parts can additionally cause wear and tear, requiring normal upkeep to stop malfunctions. Recognizing these concerns at an early stage is crucial, as timely fixings can considerably extend the life-span of the stretch wrapper and maintain perfect product packaging requirements. Resolving these usual issues warranties that companies can remain to operate efficiently and deliver items securely.

The Impact of Ignoring Repair Work on Packaging Efficiency

Enhancing Product Safety Through Routine Upkeep

Routine upkeep of stretch wrappers is vital for avoiding packaging failings that can endanger item safety and security. By resolving wear and tear quickly, firms can considerably decrease item damages and assurance that devices operates regularly. This aggressive method not just safeguards the integrity of the items however likewise enhances total operational performance.

Stopping Product Packaging Failings

Efficient upkeep of packaging equipment is vital for protecting against failures that can compromise item security. Regular examinations and prompt fixings of stretch wrappers assist recognize prospective concerns before they rise into significant problems. When stretch wrappers are well-kept, they function at peak efficiency, ensuring that items are safely covered and secured throughout storage space and transport. Preventative maintenance routines can considerably lower the possibility of mechanical failings, which typically bring about packaging errors or malfunctions. By investing in routine checks, organizations not only safeguard their products however likewise improve their general operational performance. This aggressive method decreases downtime and fosters a society of security, ultimately adding to greater customer contentment and count on in the brand name. Regular upkeep is subsequently a keystone of efficient product packaging monitoring.

Lowering Item Damages

Keeping stretch wrappers is vital for reducing product damages and ensuring security during handling and transportation. Routine upkeep of these devices assists determine and fix minor problems prior to they escalate into considerable troubles, thus maintaining the stability of the wrapped items. When stretch wrappers operate at peak performance, they give constant tension and insurance coverage, which minimizes the risk of load moving during transit. stretch wrapper repair. This integrity avoids prospective damages that can occur from inappropriate covering techniques, such as tearing or squashing of product packaging products. Additionally, properly maintained stretch wrappers add to a much safer job setting by lowering the likelihood of crashes triggered by unpredictable or inadequately wrapped lots. Ultimately, persistent upkeep plays an important function in safeguarding both products and personnel throughout the supply chain

Ensuring Regular Efficiency

Consistent performance of stretch wrappers is important for enhancing product safety throughout the supply chain. Regular upkeep plays a crucial duty in making sure that stretch wrappers run efficiently, reducing the likelihood of equipment failings that can jeopardize product packaging integrity. By regularly examining and servicing these equipments, companies can identify possible problems before they escalate, thus lessening downtime and preventing product damages. Additionally, well-maintained stretch wrappers apply uniform stress to packaging materials, making sure that loads stay secure during transportation. This integrity not just protects items from moving or falling yet also cultivates customer rely on the brand name. Inevitably, focusing on constant efficiency through routine upkeep safeguards item quality and improves security for both consumers and makers alike.

Cost-Benefit Evaluation of Spending in Repair Work Solutions

Buying fixing services for stretch wrappers can result in significant long-term savings by extending devices life expectancy and reducing the need for expensive substitutes. In addition, timely repair services assist protect against equipment downtime, ensuring regular manufacturing circulation. Boosted packaging effectiveness additionally contributes to total operational performance, making repair work services a critical consideration for services.

Long-Term Financial Savings Potential

Assessing view it now the long-lasting financial savings capacity of stretch wrapper repair service services reveals substantial expense benefits for services. By purchasing timely repair services, business can expand the life-span of their devices, decreasing the regularity of expensive substitutes. Furthermore, efficient stretch wrappers lessen product waste and assurance consistent item top quality, which subsequently improves consumer fulfillment and lowers returns.Moreover, a well-maintained stretch wrapper can result in lower energy consumption and lowered operational costs. Repair services usually feature guarantees that safeguard versus future expenditures, providing extra economic protection. Overall, the proactive approach of buying repair service services equates right into not only enhanced performance however likewise substantial savings in time, making it a tactical monetary choice for services aiming for sustainability and efficiency.

Protecting Against Tools Downtime

Prompt repair services to extend wrappers can substantially lower devices downtime, a factor that straight influences operational efficiency and earnings. When stretch wrappers malfunction, manufacturing lines can stop, resulting in hold-ups in meeting orders and prospective loss of profits. Investing in repair work solutions guarantees that equipment continues to be in peak functioning problem, useful reference decreasing the risk of unexpected breakdowns. This proactive approach not only conserves cash in the future yet additionally boosts workforce morale, as staff members can function without the stress of malfunctioning tools. Additionally, keeping constant procedures reinforces customer satisfaction through trustworthy delivery times. Ultimately, the cost-benefit evaluation of purchasing fixing services highlights the relevance of preventing downtime, as it cultivates a much more stable and productive workplace.

Improved Product Packaging Performance

A substantial improvement in packaging efficiency can be achieved via the efficient repair work of stretch wrappers. Well-kept stretch wrappers enhance product usage, decrease waste, and assurance consistent application of protective movie. stretch wrapper repair. By spending in fixing services, business can lengthen the life of their devices, minimizing the need for expensive substitutes. This proactive strategy not just preserves efficiency yet additionally decreases labor costs related to hand-operated re-wrapping or harmed pallets. Furthermore, improved devices efficiency can cause faster product packaging cycles, boosting overall throughput. Ultimately, the cost-benefit evaluation reveals that spending in stretch wrapper repair work services returns substantial returns by boosting functional effectiveness, guarding item honesty, and assuring that product packaging processes align with industry requirements for quality and safety

Picking the Right Company for Stretch Wrapper Fixes

Exactly how can one assure that the picked provider for stretch wrapper repair services satisfies both high quality and effectiveness requirements? Choosing the right company calls for careful factor to consider of several factors. First, assessing the provider's experience and proficiency in stretch wrapper repairs is essential. A well-established company with a tried and tested record can give guarantee of their abilities. Additionally, getting referrals or reviews from previous customers can use understandings into the copyright's dependability and solution quality.Furthermore, evaluating the variety of services offered is required. A detailed repair solution that consists of diagnostics, upkeep, and components replacement can assist in more reliable operations. It's also advisable to ask about the service provider's action time and accessibility for emergency repairs, as downtime can greatly influence efficiency. Finally, examining cost-effectiveness without jeopardizing quality will aid in making a knowledgeable choice that aligns with operational demands and budget plan restrictions.

Ideal Practices for Keeping Your Stretch Wrapper Devices

Maintaining stretch wrapper tools is vital for assuring peak efficiency and durability. Normal examinations must be conducted to recognize any kind of signs of wear or damage, especially in essential components such as the movie carriage, rollers, and electric motors. Keeping the equipment tidy and totally free from debris is crucial, as dirt can cause mechanical failures and inconsistent covering results. Oiling moving components according to the maker's standards will certainly boost efficiency and reduce friction. In addition, drivers must be educated to use the devices correctly, as incorrect use can cause premature wear. It is a good idea to develop a regular upkeep routine, consisting of other checks for electrical links and software application updates. Finally, preserving a sufficient supply of replacement parts on hand can stop downtime during unanticipated fixings. By adhering to these finest methods, firms can ensure their stretch wrappers operate effectively and add to general product packaging top quality and security.

Regularly Asked Concerns

Exactly how Commonly Should I Set Up Stretch Wrapper Upkeep?

Routine maintenance for stretch wrappers ought to be arranged every six months. Boosted usage or certain operational demands might necessitate extra regular checks to ensure peak efficiency and protect against unexpected malfunctions, boosting overall performance.

Can I Repair a Stretch Wrapper Myself?

Repairing a stretch wrapper individually is feasible, yet it requires technological understanding and knowledge. Errors can result in more damages, so getting in touch with an expert or describing the supplier's guidelines is often advised for efficient repairs.

What Are the Indicators My Stretch Wrapper Demands Repair?

Indicators that a stretch wrapper needs fixing include irregular wrapping stress, noticeable damage to the movie, uncommon noises throughout procedure, frequent jams, and failure to appropriately secure tons. Prompt interest is necessary to preserve performance and security.

Just how Lengthy Does a Common Stretch Wrapper Fixing Take?

The duration of a typical stretch wrapper fixing varies, frequently taking in between one to three hours, depending upon the intricacy of the problem. Elements such as components schedule and technician expertise likewise influence repair service time.

Are There Service Warranties for Stretch Wrapper Repair Work Providers?

Warranties for stretch wrapper repair solutions typically vary by company. Typically, respectable companies use limited service warranties covering parts and labor, making sure clients receive trustworthy service and protection versus defects or issues arising post-repair. Stretch wrappers, while essential for preserving product packaging integrity, can run into various functional problems that demand fixing. Identifying these problems early on is necessary, as timely repair services can substantially extend the life-span of the stretch wrapper and preserve perfect packaging requirements. Investing in fixing services for stretch wrappers can lead to considerable long-term financial savings by expanding devices life expectancy and decreasing the requirement for costly substitutes. Furthermore, reliable stretch wrappers lessen material waste and guarantee consistent item quality, which in turn enhances client complete satisfaction and reduces returns.Moreover, a well-maintained stretch wrapper can lead to lower energy intake and decreased functional prices. A considerable improvement in product packaging performance can be attained with the reliable repair of stretch wrappers.

Comments on “Which is better for your operation?”